PRODUCTS

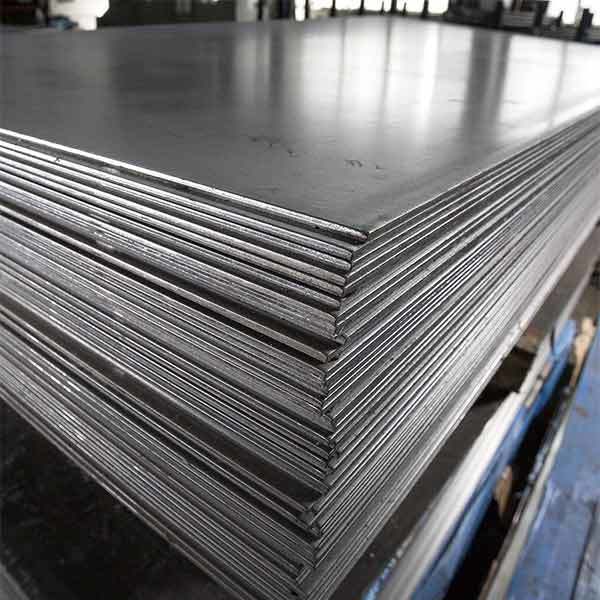

SS400 Carbon steel sheet

Category:

The technical requirements of sheet products can be divided into four aspects: (1) Thickness accuracy and uniformity; (2) Shape flatness (plate shape); (3) Surface finish; (4) Mechanical properties and physical and chemical properties . Although the requirements of these aspects are also shared by other steel plates, for thin steel plates, they are often more characteristic or more stringent in some aspects. [1] Rolling process Edit broadcast Hot rolling Cold rolling From the characteristics of the rolling deformation process, there are two fundamentally different production methods for sheet steel and strip - hot rolling and cold rolling. Laminated sheet is the oldest method of producing hot rolled sheet. The rolling equipment used is a two-roll irreversible rolling mill driven by a single roll. It is characterized by simple equipment: it does not need to be equipped with a gear rack with high cost and strict maintenance requirements, nor does it need a roll balancing device; the power equipment used is simple and economical, but it can produce the main thickness specifications in the range of 0.28-1.2 mm. sheet steel.

E-mail :

WhatsApp :

keyword :

Sheet

Carbon steel sheet

The technical requirements of sheet products can be divided into four aspects: (1) Thickness accuracy and uniformity; (2) Shape flatness (plate shape); (3) Surface finish; (4) Mechanical properties and physical and chemical properties . Although the requirements of these aspects are also shared by other steel plates, for thin steel plates, they are often more characteristic or more stringent in some aspects. [1] Rolling process Edit broadcast Hot rolling Cold rolling From the characteristics of the rolling deformation process, there are two fundamentally different production methods for sheet steel and strip - hot rolling and cold rolling. Laminated sheet is the oldest method of producing hot rolled sheet. The rolling equipment used is a two-roll irreversible rolling mill driven by a single roll. It is characterized by simple equipment: it does not need to be equipped with a gear rack with high cost and strict maintenance requirements, nor does it need a roll balancing device; the power equipment used is simple and economical, but it can produce the main thickness specifications in the range of 0.28-1.2 mm. sheet steel.

Product Description

Factory

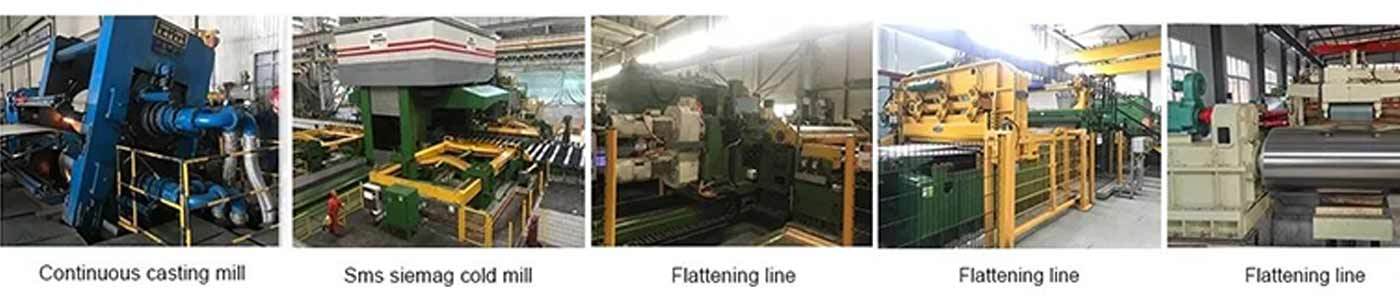

The raw materials of our factory are all high-quality steel, and the production process of regular manufacturers is fully transparent and controlled in accordance with national standards. Qualification procedures complete. Our factory has confidence in our products and promises to be responsible to the end. The company has a strong working team, experience, technology to reach industry-leading standards. The factory is located in Liaocheng City, Shandong Province. It has the largest steel pipe wholesale base in China. The products are guaranteed. Interest is guaranteed. Our factory always adheres to the business philosophy of "quality, integrity, pragmatism, enterprising, service first", and uses the company's management and operation. In the face of fierce competition, the company system is constantly improving, relying on science and technology, and continuously improving the technical content of the products sold to create higher market value for society, customers and enterprises. Our company has been building enterprises with integrity, operating the market with credibility, It has won a good reputation and the respect of domestic counterparts.

Production Process

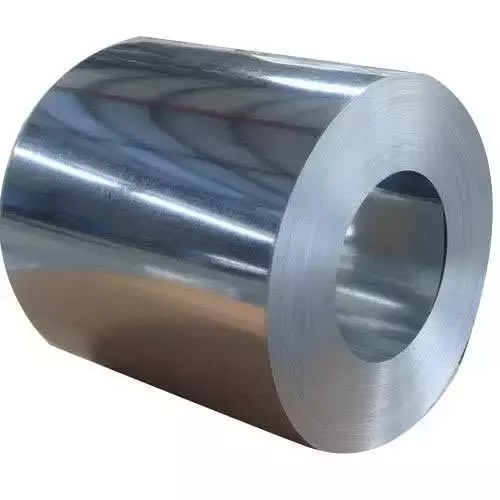

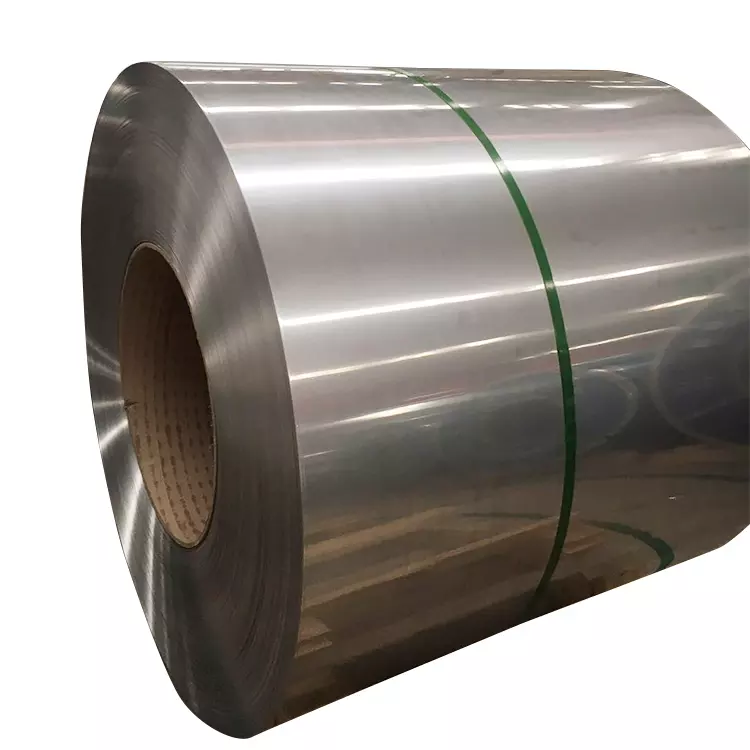

Sheet production process: Continuous hot-dip galvanizing line cold and hot-rolled steel sheets are degreasing by alkali, washed with water, dried, and then annealed in a horizontal heating furnace heated by radiant tubes. A certain amount of hydrogen is introduced into the furnace to cause reduction in the furnace. atmosphere. When heated to a certain temperature, the steel plate is cooled to a certain temperature under the protection of N2 and H2, and is immersed in zinc solution for hot-dip galvanizing under closed conditions.

Packaging Details

1. Wooden case packing, PVC packing, etc.

2. Standard seaworthy packing machine customized.

3. Port any port in China Application.

Application

Sheets are steel sheets with a thickness between 0.2 and 4 mm produced by hot rolling or cold rolling. The width of the sheet is between 500 and 2500mm. According to different uses, the sheet has different materials: ordinary carbon steel, high-quality carbon structural steel, alloy structural steel, carbon tool steel, stainless steel, spring steel, electrical silicon steel, etc. They are mainly used in the automotive industry, aviation industry, enamel industry, electrical industry, machinery industry and other sectors. Sheet steel is delivered directly after rolling, as well as pickled (pickled sheet), galvanized or tinned.

FAQ

Q: Why choose us?

A: Our company has been engaged in steel business for more than ten years, we have international experience and professionalism, we can provide customers with various high-quality steel products.

Q:What kind of payment does your company support?

A:T/T.80%L/Cat siahtCash.Western Union are all accepted,if vou have other paymentplease contact me.

Q: Can we visit your factory?

A: Warm welcome. Once we have your schedule, we will arrange for a professional sales team to follow up with you.

Q:How about the delivery time?

A:Within 15-35 days after we confirm you requirement.

Q: What is your service?

A: We will try our best to meet your requirements, we provide pre-sale service, in-sale service and after-sale service, advanced service, value-added service and personalized service.

Q: How do you keep our business in good long-term relationships?

A: 1. We maintain good quality and competitive price to ensure the interests of our customers.

Get a Free Quote

To: Shandong Weiyi Metal Products Co., Ltd.